Thermal Imaging

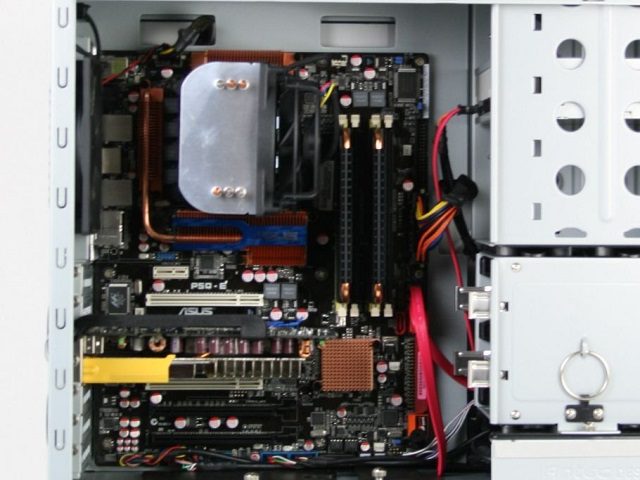

At Puget Systems, we take the quality of our computers very seriously. Because we focus on building quiet and reliable computers, long-term cooling is something we examine very closely. We have invested significantly in our QC process with Flir Systems thermal cameras. Flir cameras are powerful and accurate solution for thermal imaging and temperature measurements. They allow us to immediately identify thermal problems that would otherwise go undetected, and allow us to optimize each computer’s airflow. Its application is an excellent example of the caliber of product and process monitoring required from our quality assurance procedures.

Why is Thermal Imaging Important?

There are hundreds of microchips in a computer, but temperature sensors are only present on a few of them. Sensors are typically available on the CPU, video card, motherboard chipset, and drives. There are a handful of others scattered across the components, but the problem is that they do not give comprehensive information about the thermal behavior of each computer. When we have more complete information, we are equipped to make better decisions.

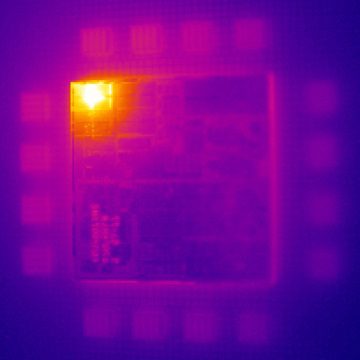

Identifying Failing Chips

Can you spot the failed portion of this microchip? It’s obvious in a thermal image!

With our equipment, we can better identify not only failed chips, but chips that are putting out an unusual amount of heat. Computer chips are semi-conductors, which means in the process of performing their logic, they convert electricity into heat. By looking for unusual patterns of heat, we can identify shorts, abnormally high workloads, and infinite loops. We can often catch problems before they result in complete chip failure.

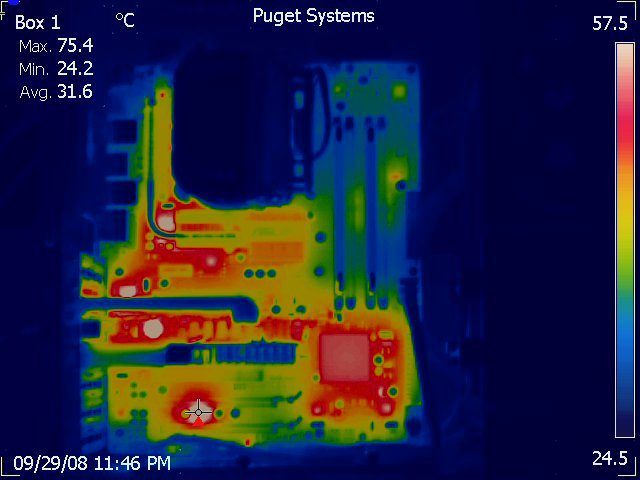

In addition to identifying failed chips, we can look closely at those which are performing properly, but are running hotter than is ideal. Since many chips do not have temperature sensors, we rely on our thermal imaging to locate these hot chips so we can make sure to adequately cool them. This will not impact the performance or short term reliability of the computer, but it will allow the computer to operate longer, without the stresses of high temperature that can lead to early failure.

Optimizing Computer Cooling and Airflow

With thermal imaging, we have a better “big picture” of the heat characteristics of a computer. With this information, we can help cool hot areas, and we can cool them more intelligently. For example, if we find that an area of the computer contains a number of hot components, we can make sure to place an exhaust fan nearby. That will allow us to cool those components, without simply blowing that hot air elsewhere in the system. In many cases, it may be perfectly acceptable for some chips to run hotter, but we can still make significant gains in the overall system temperature by exhausting hot air, when possible, rather than circulating it through the computer.

What Makes Our Process Unique?

What makes our thermal imaging unique is the same thing that makes Puget Systems unique in other areas: we are a large enough company to obtain this information, but we are also small enough to apply the information individually to each computer. The large OEMs definitely do thermal imaging, but they only do it at the system design level. With our lower volume, we are able to check a thermal view of each and every workstation we build – and we can compare with known-good reference images of similar systems. This is an excellent contribution to our innovative engineering, while maintaining our custom nature. We are very excited to be offering this service, and to use it not only to make individual improvements to each and every computer that goes out the door, but also to use this knowledge in the long term to design better computers.

If you have other questions about our thermal imaging, please feel free to contact us!