Table of Contents

If you ever need to send your Puget workstation back to our facility for diagnostics or upgrades, it's important to package the workstation correctly to avoid transit damage. Please keep in mind that Puget Systems is not responsible for damage caused by improper packing. Besides the value of the hardware itself, we understand our workstations generally contain a lot of personal data, project files, pictures, and more on the internal drives we want to make sure arrive safely. We've broken down the steps for repackaging your workstation safely below:

Packaging Materials

If your system came with Instapak expanding foam or custom bracing that was removed, start by adding the foam/bracing back in the system before proceeding with the packaging.

Cover the chassis in the plastic bag

To protect the paint from being rubbed off by the styrofoam, we cover the chassis with a plastic bag.

Attach the top and bottom styrofoam inserts to the chassis

The top and bottom foam inserts protect the chassis from shock and movement in the inner box. Please note that these are distinctly different pieces and if the top foam is placed on the bottom, the system may not fit correctly in the box.

Place system and styrofoam in inner box

Using a double box standard helps protect the chassis from penetration and shock damage.

Add the foam corners around the inner box

The 8 foam corners space the inner box away from the outer box.

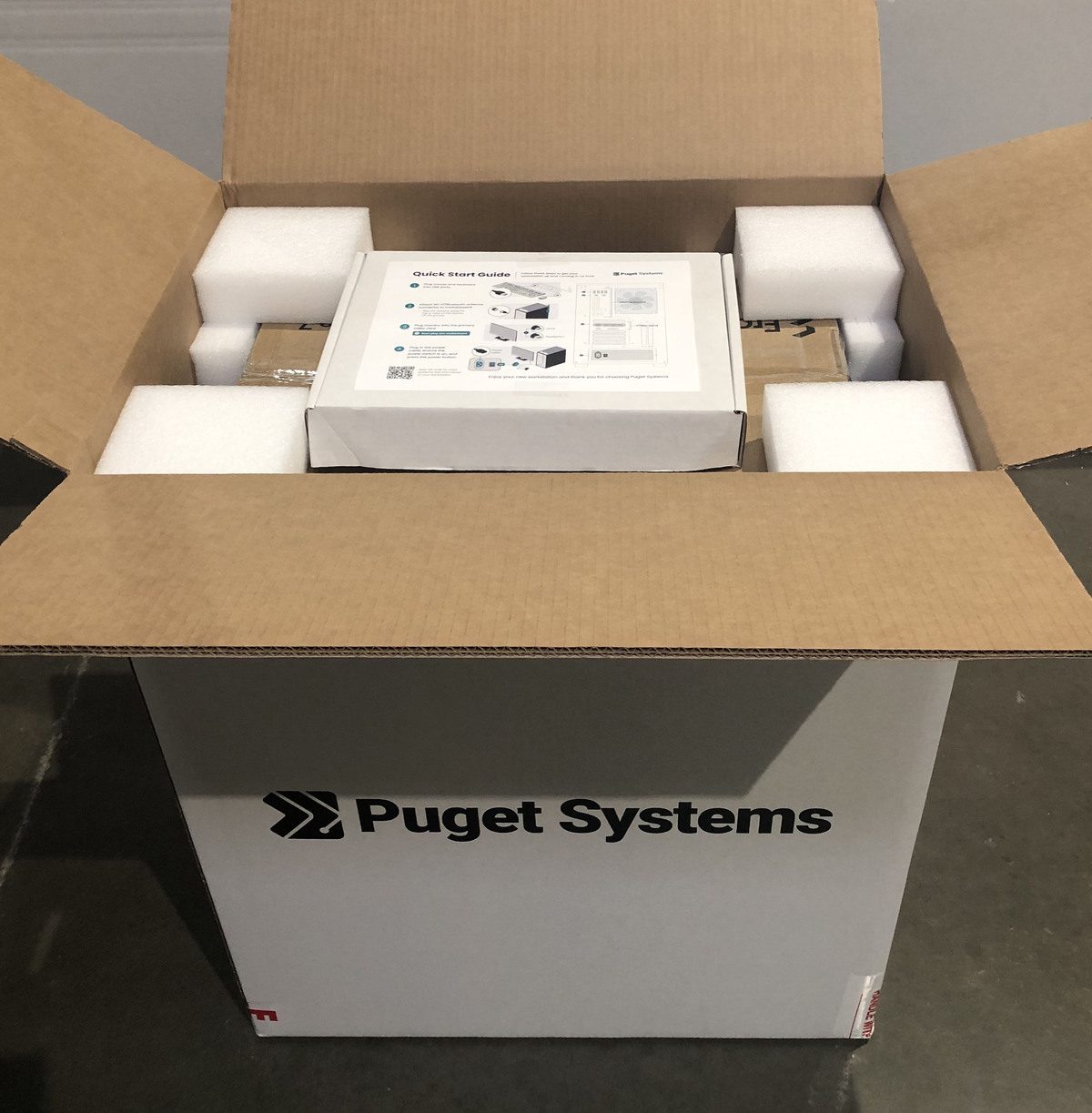

Place Inner box, foam corners, and accessories box in the outer box

We use the accessories that came with your system to validate WiFi/Bluetooth connection and other peripheral compatibility. If you are unable to include the accessories that came with your system, let our Support team know.

No longer have the original packaging materials?

If the original packaging materials that came with the system weren't kept or are damaged, there is a possibility we will have spare packaging materials for purchase. Please reach out to our Support Team for availability and pricing.